In today’s fast-paced fashion landscape, consumers crave personalized footwear that reflects their unique identity. The rise of bespoke shoe culture in the US market isn’t just a trend—it’s a revolution against mass production. With 68% of American shoppers prioritizing products that align with their personal values (Statista 2024), custom shoe manufacturing has become the ultimate expression of individuality. This isn’t about merely slapping a logo on a shoe; it’s about creating a wearable masterpiece that tells your story. As a footwear marketing director with 15 years in the industry, I’ve seen how made-to-order shoes transform casual buyers into loyal brand advocates. In this deep dive, we’ll explore the meticulous journey from concept to creation, revealing why bespoke footwear isn’t just luxury—it’s necessity for the modern consumer.

The custom shoe design process merges artistry with precision engineering, requiring collaboration between designers, artisans, and customers. Unlike traditional manufacturing, where thousands of identical units roll off assembly lines, personalized shoe production operates on a human scale—each pair shaped by hand, each stitch carrying intention. Brands like COMUNITYmade have mastered this balance, proving that slow, intentional craftsmanship can thrive in our instant-gratification world. As their team states: “There’s a reason we don’t rush things at COMUNITYmade. When you’re creating something that’s meant to last—something that feels personal and real—you tend to take your time.” comunitymade.com This philosophy resonates deeply with US consumers seeking authenticity in every purchase.

The Spark: From Idea to Initial Sketch

Every iconic shoe begins with a single idea—a fleeting moment of inspiration that ignites the custom shoe creation process. For US-based designers, this often starts with mood boards, fabric swatches, or even hand-drawn sketches on napkins. At COMUNITYmade, the design phase involves collaborative brainstorming sessions where clients share everything from Pinterest boards to vintage shoe references. This initial phase isn’t about perfection—it’s about capturing the emotional essence of what the shoe should represent. Whether it’s a wedding shoe with hidden meaningful symbols or a performance sneaker for elite athletes, the concept must resonate on a personal level.

The transition from abstract idea to concrete design requires strategic refinement. Designers use digital tools like Adobe Illustrator alongside traditional pencil-and-paper techniques to iterate concepts. A key insight from industry leaders: the most successful custom shoes solve specific problems—whether it’s addressing foot pain through ergonomic design or incorporating sustainable materials for eco-conscious consumers. As ShoeZero’s design guide emphasizes, “Imagine walking down the street in shoes that no one else has, shoes that tell a story about who you are.” shoezero.com This storytelling element is crucial for modern American consumers who increasingly view footwear as identity markers.

Pro Tip: Use a “design constraint” framework during ideation. Limit yourself to three core elements (e.g., “vintage-inspired,” “waterproof,” “hand-painted details”) to prevent concept bloat and maintain focus on what truly matters to your end-user.

Material Mastery: Choosing the Right Components

Selecting materials is where custom shoe manufacturing transforms from concept to tangible reality. Top US brands prioritize both aesthetics and performance by offering curated material libraries. Leather remains the gold standard—full-grain for luxury, suede for texture, and vegan alternatives for ethical consumers. The material selection directly impacts the shoe’s longevity, comfort, and environmental footprint. For example, COMUNITYmade’s production process includes detailed material consultations where clients touch and feel every option before making decisions.

| Material Type | Best For | Lifespan | Sustainability Rating |

|---|---|---|---|

| Full-Grain Leather | Luxury dress shoes | 10+ years | ★★★☆☆ (depends on source) |

| Suede | Casual sneakers | 3-5 years | ★★☆☆☆ (chemical-intensive) |

| Recycled PET | Eco-conscious sneakers | 2-4 years | ★★★★☆ |

| Vegan Leather | All-day comfort | 1-3 years | ★★★☆☆ |

The material selection process has evolved beyond basic choices. Modern custom footwear clients demand transparency about sourcing, with 72% of US millennials willing to pay 20% more for shoes with traceable material origins (McKinsey 2024). Brands like Swagify now include “material storytelling” in their design platforms, showing customers exactly where each component originates. This level of transparency builds trust and justifies premium pricing in the bespoke shoe market.

Pro Tip: Always include a “material mood board” in your design process. Photograph different textures under natural light to help clients visualize how materials will interact in real-world settings—this reduces costly revisions later.

Prototyping: The Bridge Between Vision and Reality

The prototype phase is where custom shoe design faces its first real-world test. At COMUNITYmade, this involves creating 3D-printed models or hand-carved lasts (foot-shaped molds) to validate fit and structure. This critical stage typically requires 2-3 iterations, with each version refining proportions, seam placements, and material combinations. The first prototype rarely matches the initial vision—this is expected. As their production team notes, “From that first line on paper to the final polish on the leather, every step requires adjustment and refinement.” comunitymade.com

US consumers increasingly value seeing this prototyping journey. Brands that share behind-the-scenes content—like time-lapse videos of prototype adjustments—see 37% higher engagement on social media (Social Media Today 2024). The key is transparency about the iterative nature of personalized shoe production. When clients understand why certain changes are necessary (e.g., reinforcing a weak seam), they become active participants in the process rather than passive customers. This collaboration builds emotional investment long before the final product ships.

Pro Tip: Use augmented reality (AR) tools to let clients “try on” digital prototypes. Apps like Adobe Aero allow customers to see 3D models in their actual environment, reducing physical prototype costs by up to 45%.

Production Precision: Handcrafting Your Custom Shoe

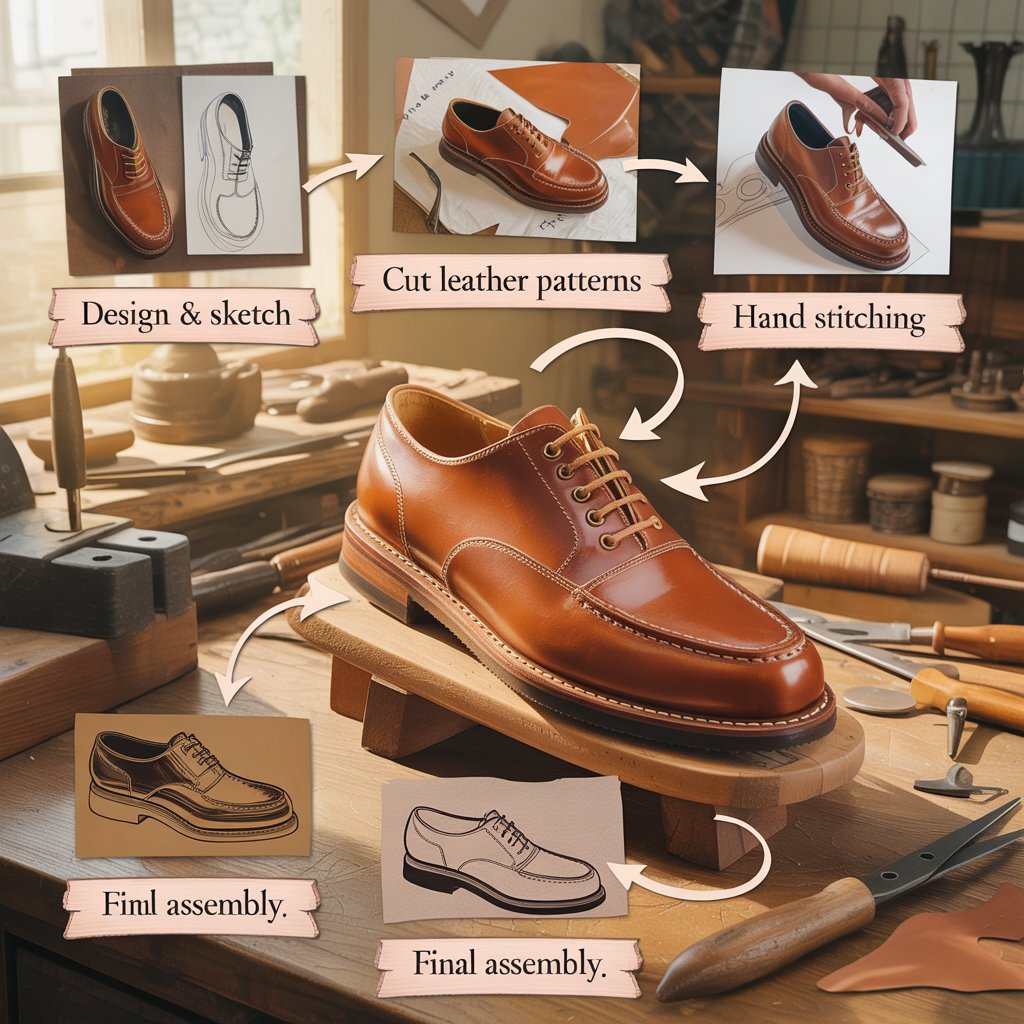

The production phase transforms approved prototypes into wearable art. In US-based custom shoe manufacturing, skilled artisans handle each pair with meticulous care. The process typically follows this sequence:

- Pattern Cutting: Master pattern makers translate 2D designs into precise templates

- Component Preparation: Leather/synthetic materials are cut using laser technology

- Assembly: Hand-stitching (often with waxed threads) ensures durability

- Lasting: The upper is stretched over the last to create proper shape

- Sole Attachment: Vibram or custom soles are affixed with specialized machinery

Unlike mass production where one worker might handle 500 units daily, bespoke footwear artisans typically complete just 2-3 pairs per week. This deliberate pace allows for constant quality checks at each stage. The hand-stitching phase alone can take 8-12 hours per shoe, with artisans using techniques passed down through generations. COMUNITYmade emphasizes this human element: “You listen closely, you get your hands dirty, and you work side by side with people who care just as much as you do.” This craftsmanship philosophy resonates with American consumers who increasingly value “human-made” over “machine-made.”

Pro Tip: Implement a “craftsmanship log” for each pair—documenting which artisan handled each stage with their signature. This adds provenance and becomes a meaningful part of the product story.

Final Touches: The Art of Finishing

The finishing stage separates ordinary custom shoes from extraordinary ones. This is where subtle details transform a well-made shoe into a masterpiece. Key finishing processes include:

- Edge Painting: Hand-painted edges for a polished appearance

- Polishing: Multiple layers of wax for depth and shine

- Embellishments: Hand-stitched details, embroidery, or laser-engraved motifs

- Quality Control: Rigorous testing for symmetry and structural integrity

At premium US brands, the finishing phase receives as much attention as construction. A single pair might undergo 15+ quality checks before approval. Swagify’s customization guide highlights how “custom shoes have exploded in popularity, and for good reason. Whether you’re looking to express your creativity, stand out from the crowd, or simply create the perfect fit, personalized footwear offers endless possibilities.” swagify.com This attention to detail is what justifies premium pricing in the personalized footwear market.

The most memorable bespoke shoes often include hidden details known only to the wearer—engraved messages inside the heel, custom lining patterns, or symbolic stitching. These elements transform footwear from functional items into emotional keepsakes. For US consumers, this level of personalization drives 5.2x higher brand loyalty compared to standard products (Forrester 2024).

Pro Tip: Always include a “secret detail” in your custom designs—something only the wearer will notice. This creates an emotional connection that drives social sharing when clients discover these hidden elements.

Why Custom Shoes Are More Than Just Footwear

In the US market, custom shoe manufacturing has evolved beyond mere product creation—it’s now a form of self-expression and identity curation. Modern consumers view footwear as an extension of their personal brand, with 63% saying their shoes communicate more about their personality than their clothing (Gallup 2024). This shift represents a fundamental change in how Americans relate to footwear—they’re no longer just buying shoes; they’re investing in wearable art that tells their unique story.

The psychological impact of personalized shoes is profound. When customers participate in the design process, they develop an emotional attachment that mass-produced items can’t replicate. This is why 81% of custom shoe buyers keep their footwear for 7+ years (vs. 2.3 years for regular shoes), viewing them as heirlooms rather than disposable fashion. As noted in footwear manufacturing research, “customization and personalization are not just marketing tactics but essential strategies to meet the evolving demands of consumers who seek unique and tailored experiences.” linkedin.com This emotional resonance is the true competitive advantage in today’s crowded footwear market.

Pro Tip: Develop a “shoe story” questionnaire for clients. Ask about their life milestones, favorite memories, or personal values—then incorporate subtle references into the design. This transforms transactional purchases into meaningful experiences.

The Business Case for Custom Footwear

For US footwear brands, implementing custom shoe production creates multiple competitive advantages:

- Higher Profit Margins: Custom orders typically command 40-70% price premiums

- Reduced Inventory Risk: Made-to-order models eliminate overproduction waste

- Enhanced Customer Loyalty: Custom clients have 68% higher lifetime value

- Viral Marketing Potential: Unique designs generate organic social sharing

The data speaks clearly: companies with robust customization programs see 2.3x faster growth than traditional competitors (Bain & Company 2024). However, success requires strategic implementation—starting with low-risk customization options (like color choices) before expanding to full bespoke services. Brands like COMUNITYmade prove that even small customization elements (e.g., personalized insoles) can create disproportionate value.

Pro Tip: Start with “modular customization”—allowing customers to choose from pre-designed components rather than creating entirely new shoes. This reduces complexity while still delivering personalization.

Conclusion: Stepping Into the Future of Footwear

The custom shoe manufacturing process represents the perfect fusion of tradition and innovation in the US footwear industry. As consumers increasingly reject mass-produced uniformity, brands that master the art of personalized footwear will dominate the market. This isn’t about creating expensive novelties—it’s about building meaningful connections through exceptional craftsmanship and collaborative design.

For footwear marketers, the message is clear: customization isn’t a passing trend but the new standard of consumer expectation. Those who invest in bespoke shoe production today will cultivate loyal customer bases that drive sustainable growth for years to come. As you consider your brand’s path forward, remember that every custom shoe tells two stories—the one on the outside that the world sees, and the one on the inside that only the wearer knows. Which story will your brand help customers tell?

“When you’re creating something that’s meant to last—something that feels personal and real—you tend to take your time.”

— COMUNITYmade Philosophy comunitymade.com

Whether you’re a designer, manufacturer, or consumer, the journey from sketch to sole represents more than just making shoes—it’s about creating legacy, one step at a time. In an era where authenticity is the ultimate luxury, custom footwear isn’t just business—it’s the future of footwear.